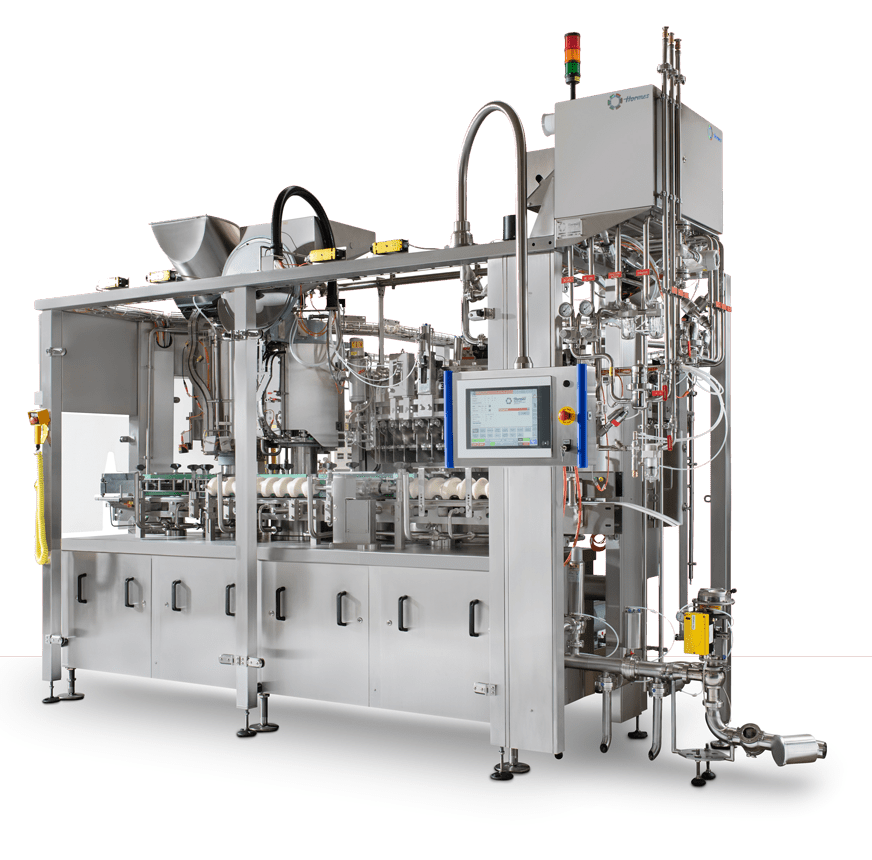

Hormes filling

Hormes filling equipment - strictly customer oriented.

Hormes filling equipment is consistently geared to your needs. Whatever you need, we supply it for almost any product:

Be it soft drinks, beer, beverages with and without CO2, yogurt, milk, juices, sparkling wine, smoothies, edible oil, sauces, spirits, lumps, wine, of course combinations are also possible, systems such as pressure fillers, vacuum fillers, piston fillers or fillers with flow measurement technology or filling probes are used. With cappers for corks, screw caps, sports caps.

You have the product, we have the state-of-the-art filling technology.

Hormes filling lines are energy-efficient, resource-saving, sustainable and cost-effective in maintenance.

Short set-up times Weight- and hygiene-optimized format parts for product changeover We only use energy-efficient drives User-friendly concept with low maintenance, no lubrication of drives required

Consistently hygienic and easy to clean thanks to “open frame” stainless steel construction Robust and durable filling technology thanks to the use of high-quality components without exception

Hormes PDA: full control over production using Hormes store floor data collection – at any time, from any place and almost any terminal. Sensors record all data of the filling process and display them in a graphical user interface, in the browser, on the tablet at home, anywhere.

on request with complete glass enclosure according to our “hygiene first” concept

guaranteed assured spare parts supply: you will not experience “is no longer produced” with us, we have been producing beverage filling machines for our customers for 85 years and securely guarantee the spare parts supply for the entire life cycle of all machines

In addition to our own designs, we also offer modernized machines from well-known manufacturers such as KHS or Krones: after complete disassembly, glass bead blasting, galvanizing, painting of the beverage fillers, basic components are replaced with new parts, new electronics, high-end pneumatic components.

And because we are also convinced of the quality of our work with our CE-certified “Retrofit Fillers”, we provide a two-year warranty, as we do with our new machines.

As beverage machine professionals, we are also happy to carry out any kind of service, repair or conversion on your machines. Not just for the Hormes filling line.

Contact us and we will find a solution together.

Are you looking for something in particular?

Enter your search term above and we’ll take care of the rest.

Our Clients

Contact

Wilhelm Hormes Ing. GmbH & Co. KG

Bunner Strasse 4

49632 Essen/Oldenburg

Germany

Phone: +49 (0) 54 34 – 9 44 40

Fax: +49 (0) 54 34 – 39 48

Mail: info@hormes.de

Follow us

Back again?

Our Site

Suchen Sie etwas Bestimmtes?

Geben Sie oben Ihren Suchbegriff ein und wir kümmern uns um den Rest.

Hormes – © 2022