Process Technology

Hormes Prozesstechnik – Plants for beverage production

What do you need?

Just tell us what you want to produce – we will build your vision.

Fast. Customized. Technically perfect and energy-efficient.

For the efficient production of your beverages, we offer the right solution in process technology, as individual as your product.

The only thing that remains constant is our quality.

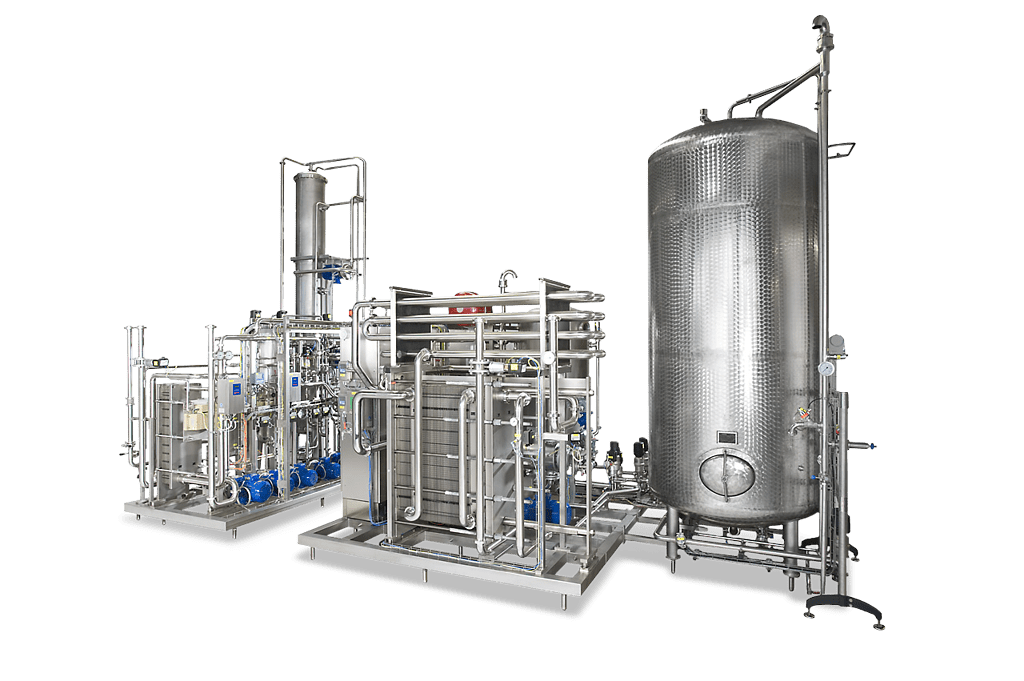

CIP systems

Hormes offers CIP systems that are optimally adapted to your cleaning requirements. Depending on the task, the size and degree of automation are designed accordingly.

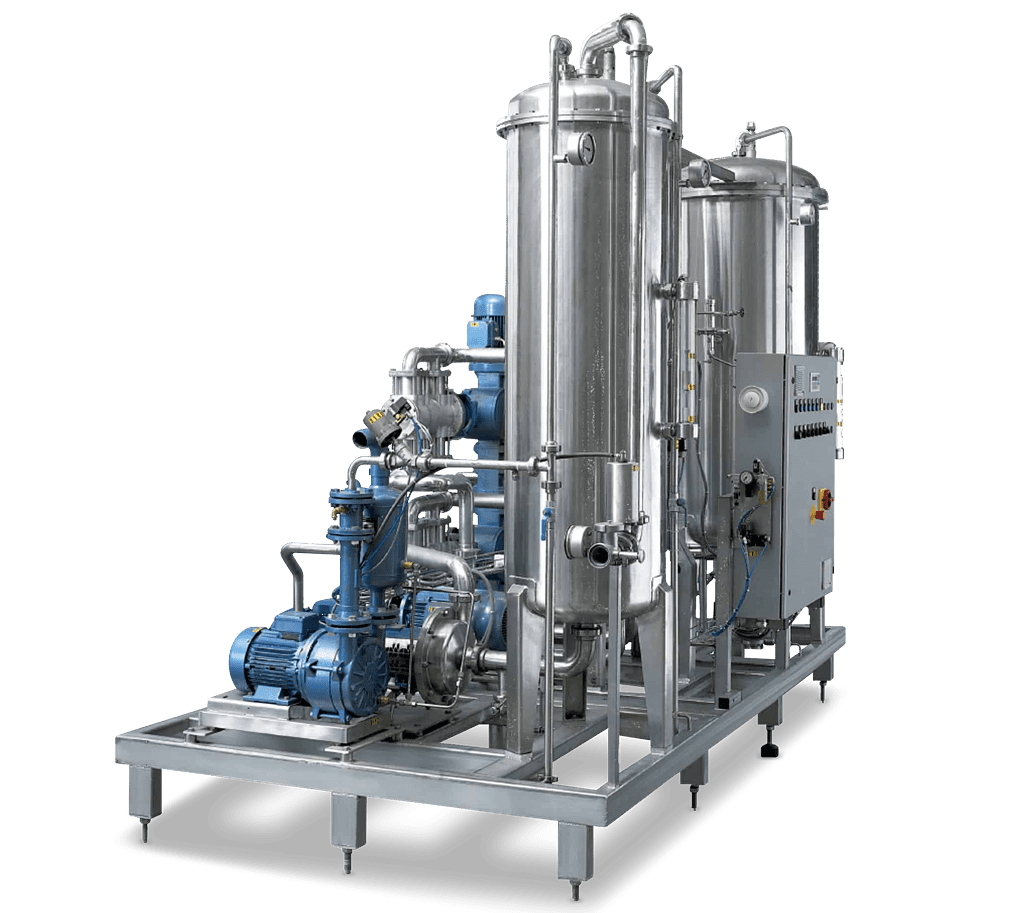

The flash pasteurizer

As an alternative to the tunnel pasteurizer, the flash pasteurizer (flash pasteurizer) can be used to optimize the shelf life of beverages before filling. This heat treatment process is energy-efficient and cost-effective.

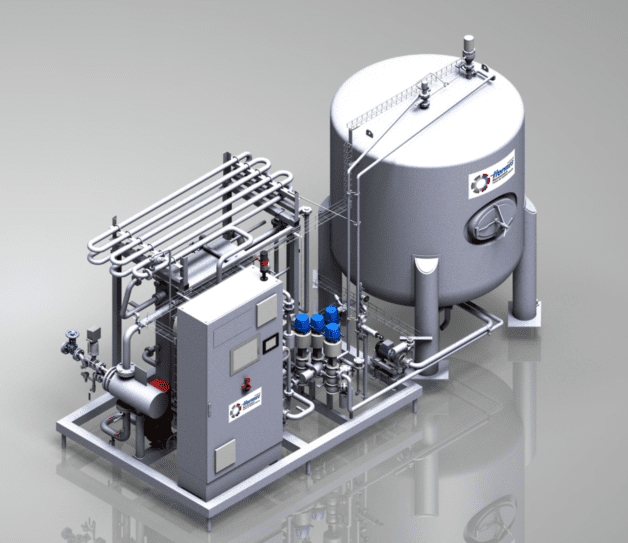

Mixers

For the efficient production of your beverages Hormes offers the suitable solution. Optimal results are achieved with combinations of blending and carbonation equipment, as well as upstream degassing.

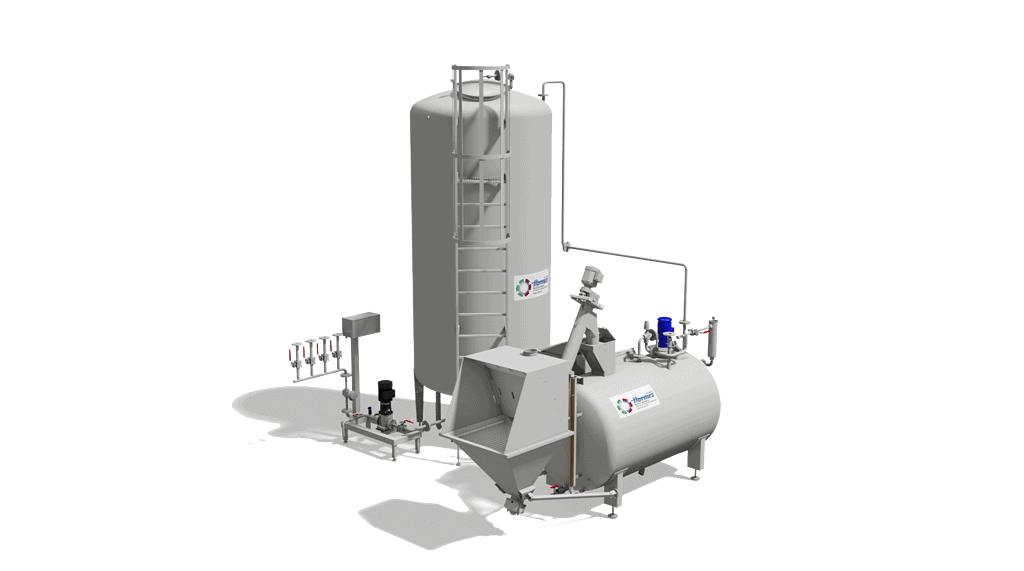

Caustic solution plant

For the preparation of caustic soda from solids (flakes/pallets) Wilhelm Hormes GmbH & Co. KG offers a modular plant, which is configured according to the requirements.

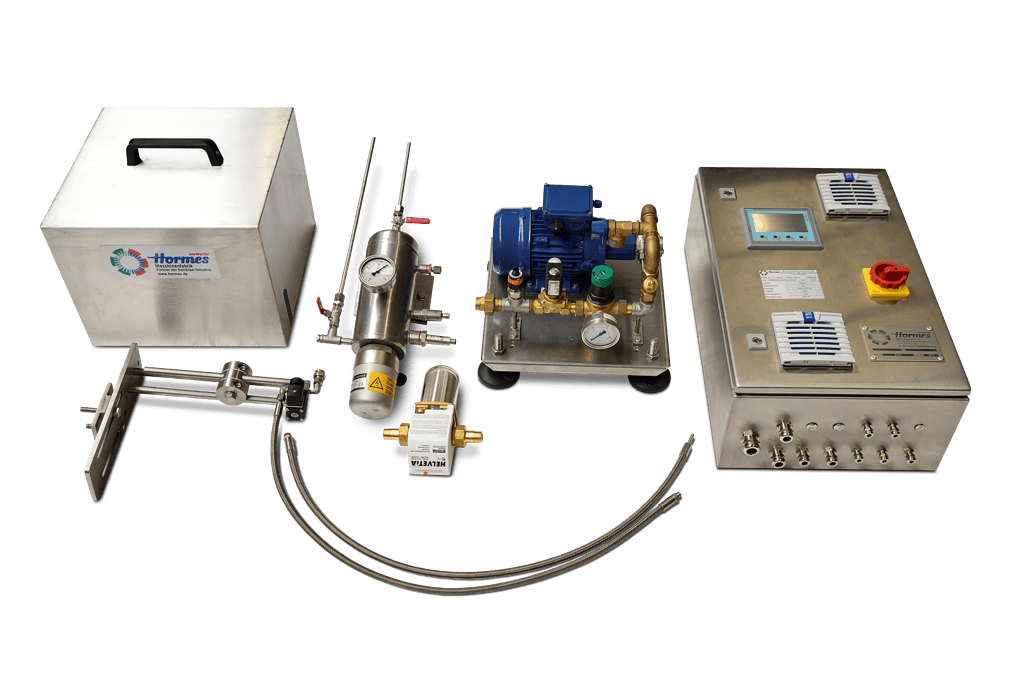

High Pressure Injection (HPI)

Foaming device for beer beverages as a technical upgrade. For reduction of oxygen in the bottle neck after the filling process.

Caustic sedimentation

During bottle cleaning, it is important to use the caustic soda from the bottle washer efficiently. Our sedimentation systems extend the caustic service life and save energy.

Are you looking for something in particular?

Enter your search term above and we’ll take care of the rest.

Our Clients

Contact

Wilhelm Hormes Ing. GmbH & Co. KG

Bunner Strasse 4

49632 Essen/Oldenburg

Germany

Phone: +49 (0) 54 34 – 9 44 40

Fax: +49 (0) 54 34 – 39 48

Mail: info@hormes.de

Follow us

Back again?

Our Site

Suchen Sie etwas Bestimmtes?

Geben Sie oben Ihren Suchbegriff ein und wir kümmern uns um den Rest.

Hormes – © 2022