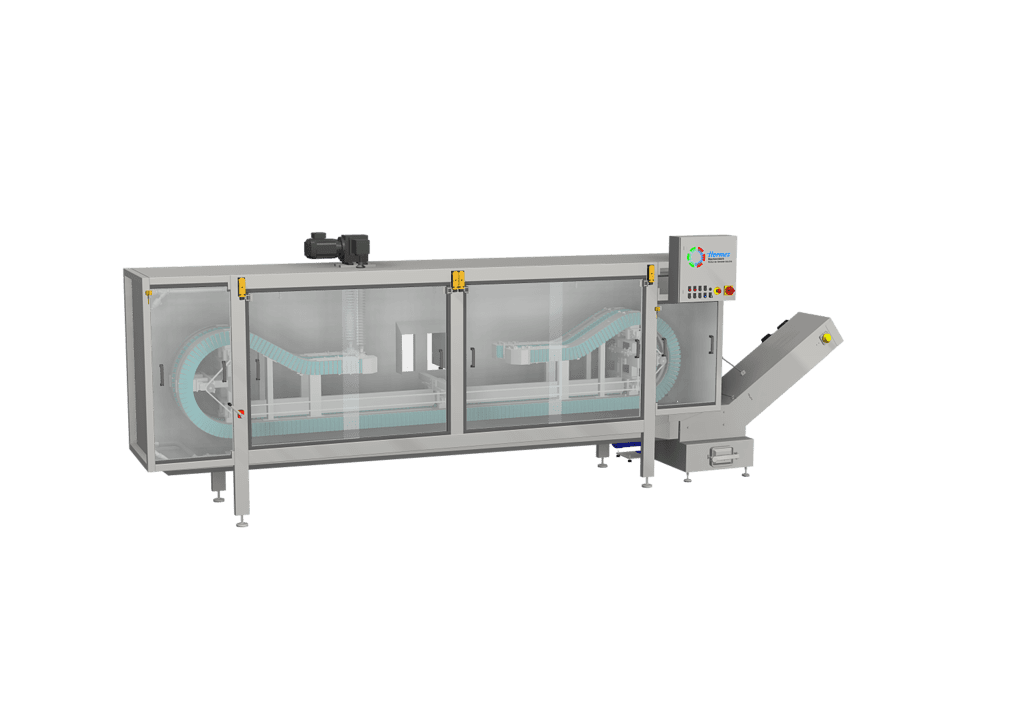

For the cleaning of glass products, PET bottles and cans

The linear rinser from HORMES can be used in many ways thanks to its modular design and various equipment features. It facilitates the emptying and cleaning of jars, bottles and cans. The containers can be cleaned not only with water but also with air or a chemical component.

Customer-oriented all along the line - special features at a glance:

Automated

From format changeover to dirt discharge and cleaning of the machine, many functions can be automated according to customer requirements.

Hygiene

Nozzles make it possible to automatically clean the inside of the entire machine. Even the conveyor chain can be automatically rinsed at freely selectable intervals.

Optimally designed

The length, performance and conveying speed of the machine are optimally adapted to your existing production process so that it matches perfectly with the required emptying, spraying and dripping times.

Cleaning

The cleaning of the machine after the end of production or between two production shifts can be fully tailored to the customer's needs. From cold manual cleaning to cleaning via CIP pump and rotating nozzles, everything is possible.

Technical data

Our standard

- Conveying capacity: max. 50,000 units/h

- Container width: 30 – 150 mm

- Container weight: up to 30 kg

- Overhead distance: up to 10 m

- Solid frame construction in stainless steel

- Automatic chain tensioning

- Manual height adjustment of the nozzle lance

- Manual aisle width adjustment

- Chain lubrication with grease/water

Optional features

- Rotating deflection pulleys in the curves for better running and longer service life

- Fully automatic aisle width adjustment

- Fully automatic height adjustment of the nozzle lance/air lance

- Complete machine cladding with doors made of Makrolon/stainless steel

- Suction system for blown out particles

- Fully automatic flushing with water via rotating cleaning nozzles

- Control system with jam monitoring

- Automatic dirt discharge

- Feed pump/ waste water pump

- Sterile air unit

- Chemical dosing unit

Are you looking for something in particular?

Enter your search term above and we’ll take care of the rest.

Suchen Sie etwas Bestimmtes?

Geben Sie oben Ihren Suchbegriff ein und wir kümmern uns um den Rest.

Dirt discharge

The linear rinser is often used to empty residues from yogurt jars or milk bottles in dairies in order to prevent contamination of the caustic solution in the bottle washer. In this case, an additional dirt discharge system is recommended, which also conveys foreign bodies such as spoons or shards out of the machine.

Waste water pump in detail

Modern pumps are used to pump off the splash water and dirty water and supply the CIP cleaning system with sufficient CIP medium.

Manual aisle width adjustment

Manual or automated aisle width adjustment allows the format to be continuously adjusted. This makes it possible to change to a different format quickly and easily.

Automatic Chain Cleaning

Flexible flush lines are used to cyclically rinse the carrier chain and its guide.

The rinsing interval can be freely selected in the program depending on the degree of contamination of the empties.

This ensures optimal grip of the chain and a perfect cleaning result at all times.

Inquire now!

Reduce it to the Max:

Why buy multiple standalone units when you can have one versatile multi-purpose-device?

Suchen Sie etwas Bestimmtes?

Geben Sie oben Ihren Suchbegriff ein und wir kümmern uns um den Rest.

Are you looking for something in particular?

Enter your search term above and we’ll take care of the rest.

Our Clients

Contact

Wilhelm Hormes Ing. GmbH & Co. KG

Bunner Strasse 4

49632 Essen/Oldenburg

Germany

Phone: +49 (0) 0 54 34 – 9 44 40

Fax: +49 (0) 0 54 34 – 39 48

Mail: info@hormes.de

Follow us

Back again?

Our Site

Suchen Sie etwas Bestimmtes?

Geben Sie oben Ihren Suchbegriff ein und wir kümmern uns um den Rest.